Monday, September 8, 2008

Display problem ? Click HERE

This post would like to bring to you a very special software for Chemistry Periodic Table. It has been developed by Paul Alan Freshney. Chemistry Periodic Table software has been there since 2002 and latest version is 3.7, border="0" released on AUGUST 31, 2008 (as of now).

The application contains ALL the elements of the Periodic Table along with images of the elements in their natural state, as well as lots of other information and interactive displays.

There are some very interesting features in this Chemistry Periodic Table :

- Detailed information on each element

- Details of isotopes and allotropes

- Details of important compounds

- Details of reactions with water, air, halogens and acids

- Images for each element (300+ images in total) including valence and crystal stucture diagrams

- Glossary of terms

- Graphs of important element properties and trends

- Biographies for the important scientists and element discoverers

- View the states of the elements at any temperature (from 0 - 6000k)

- XP style support

- Search through all content

- Electron shell diagrams of each element (including orbital images)

- Atomic width diagram

- Toolbox, 330 physical constants and over 6400 formulae

- Element names and the majority of the applications buttons are now available in eight different languages. Unfortunately there is just too much text for me to translate (100000+ words).

Some snapshot of this software.

You may add your own content to the software as well.

Download (Click here)

Related Topic

You may add your own content to the software as well.

Download (Click here)

Related Topic

- Periodic Table of Videos for Element

- FREE & reliable Pressure Relief Valve Sizing Software

- FREE & Reliable Control Valve Sizing Software

- KG-TOWER® - FREE Column hydraulic rating software from Koch-Glitsh...

- SULCOL: FREE tower internals design package

- Useful Steam - Condensate Calculator

- SteamTab - A simple Executable file for Steam - Water Properties...

Labels: Education, Learning, Software

Monday, April 28, 2008

Display problem ? Click HERE

The following Series / Parallel Pump Calculator (EXCEL) has been generated to allows to mix two pump curves and produce a combined performance curve of identical and similar pumps (or pumps with different performance) operate in series and parallel. It also allows you to enter system curve so that you can evaluate their performance. In this Calculator, the unit for head can be feet, meter, mmHg and flow can be gpm, m3/h, etc

Saturday, February 23, 2008

Display problem ? Click HERE

One fine day, you are in the meeting and you have been asked to about the properties for steam at 10 barg & 200 degC. You can either

One fine day, you are in the meeting and you have been asked to about the properties for steam at 10 barg & 200 degC. You can either - use the excel add-on Water97_v13 as introduced in "Conduct Steam-Water Balance MANUALLY using Water97_v13"

- use the Steam-Condensate calculator as introduced in "Useful Steam - Condensate Calculator"

- Steam table (manual calculation)

Use Excel may required to remember the function and steam-condensate may required you to login to internet. Sometime the server which steam-condensate calculator may down for some reason. Using steam table would definitely time consuming. One of way is to use the SteamTab steam-condensate software which is rather handy for you.

Use Excel may required to remember the function and steam-condensate may required you to login to internet. Sometime the server which steam-condensate calculator may down for some reason. Using steam table would definitely time consuming. One of way is to use the SteamTab steam-condensate software which is rather handy for you.Similar to the excel add-on, you may obtain steam-condensate properties for subcooled, saturated and superheated condition. In additional to common properties, it also calculated other parameter such as surface tension, Gibbs energy, etc.

If you have problem in obtaining this handy tool, please drop me a note.

If you have problem in obtaining this handy tool, please drop me a note.

Related Topic

- Useful Steam - Condensate Calculator

- Steam - Condensate Useful Links...

- FREE & Reliable Control Valve Sizing Software

- Steam in FIRE...

Thursday, February 14, 2008

Display problem ? CLICK HERE

Recently i was supervising a young engineer in the design of Steam - Water system for an LNG plant. This kind of system can be easily simulated in any Process Simulator such as HYSYS, PRO-II, etc and generate a Heat & Material Balance (HMB). If you have several years experience, you may notice that nowadays young engineer tends to use Process simulator and ignoring the basic behind. Due to this reason, i insisted the young engineer to conduct Heat & Material Balance for Steam -water system MANUALLY using Excel spreadsheet. Without any surprise the young engineer having difficulties...

Recently i was supervising a young engineer in the design of Steam - Water system for an LNG plant. This kind of system can be easily simulated in any Process Simulator such as HYSYS, PRO-II, etc and generate a Heat & Material Balance (HMB). If you have several years experience, you may notice that nowadays young engineer tends to use Process simulator and ignoring the basic behind. Due to this reason, i insisted the young engineer to conduct Heat & Material Balance for Steam -water system MANUALLY using Excel spreadsheet. Without any surprise the young engineer having difficulties... In "Useful Steam - Condensate Calculator", there is an Excel Add-in (Water97_v13.xla or Alternative download) available FREE for download, is very useful for calculating thermodynamic and transport properties of water and steam using the industrial standard IAPWS-IF97. In this post, i will elaborate a little bit on the method to conduct steam-water balance manually using above add-in.

Material Balance :

For M1 :

M1 & M2 can be adjusted until the enthalpy difference between INLET section (e.g. M1 x h1,vs + M2 x h2,T ) and OUTLET section (e.g. M3 x h3,vs) equal to zero AND M1+M2 = M3. The adjust function can be easily setup using GOAL SEEK feature in EXCEL.

Details may refer to following image.

It is rather simple programming as seen from above and no simulator is required.

Problem statement :High pressure steam (HS) at 20 barg @ saturated condition mix with Boiler Feed Water (BFW) at 15 barg @ 60 degC to 1000 kg/h Low Pressure Steam (LS) at 3.5 barg @ Saturated condition. Find quantity of HS & BFW.

Material Balance :

M1 + M2 = M3Heat Balance :

M2 = M3 - M1

M1 x h1,vs + M2 x h2,T = M3 x h3,vsa) For HS Steam : Get Specific enthalpy (h1,vs) for Saturated steam at pressure 20 using enthalpySatVapPW (P)

M1 x h1,vs + (M3-M1) x h2,T = M3 x h3,vs

M1 x h1,vs + M3 x h2,T - M1 x h2,T = M3 x h3,vs

M1 x h1,vs - M1 x h2,T = M3 x h3,vs - M3 x h2,T

M1 x (h1,vs - h2,T) = M3 x (h3,vs - h2,T)

M1 = M3 x (h3,vs - h2,T) / (h1,vs - h2,T)

[e.g. enthalpySatVapPW(20+1.01325)]b) For BFW : Get Specific enthalpy (h2,T) for Subcooled liquid at 15 barg @ 60 degC using enthalpyW(T,P)

[e.g. enthalpyW(60+273.15, 15+1.01325)]c) For LS Steam : Get Specific enthalpy (h3,vs) for Saturated steam at pressure 3.5 using enthalpySatVapPW (P)

[e.g. enthalpySatVapPW(3.5+1.01325)]d) As M3 is 1000 kg/h, M1 & M2 can be obtained by modeling it in the EXCEL sheet.

For M1 :

=1000 * (enthalpySatVapPW(3.5+1.01325) - enthalpyW(60+273.15,15+1.01325))/ (enthalpySatVapPW(20+1.01325) - enthalpyW(60+273.15,15+1.01325))For M2 :

= 1000 - M1Another method is using GOAL SEEK in EXCEL sheet...

M1 & M2 can be adjusted until the enthalpy difference between INLET section (e.g. M1 x h1,vs + M2 x h2,T ) and OUTLET section (e.g. M3 x h3,vs) equal to zero AND M1+M2 = M3. The adjust function can be easily setup using GOAL SEEK feature in EXCEL.

Details may refer to following image.

It is rather simple programming as seen from above and no simulator is required.

Young engineer is always encourage to conduct above calculation as least 2-3 times so that you are sure yourself understand heat & material balance in depth. By doing this kind of calculation, you will surprise your depth understanding. Later stage, you can always simulate balance with process simulator to save time.

For those who are interested in the EXCEL spreadsheet, you may drop a note to me.

Related Topic

For those who are interested in the EXCEL spreadsheet, you may drop a note to me.

Related Topic

- Useful Steam - Condensate Calculator

- Steam - Condensate Useful Links...

- FREE & Reliable Control Valve Sizing Software

- aspenONE V2006.5 ... RELEASED

- FREE & reliable Pressure Relief Valve Sizing Software

- Paul Muller - Process Solution Provider...@Heat Exchanger

- Optimized Gas Treating, Inc. (OGT) - Experts in CO2-Amine

- ChemSep™ LITE - FREE Distillation, Absorption & Extraction Simulation

Wednesday, February 13, 2008

Recommended Utility : LOCKIMAGE - Passwaord Protect Images

One fine day you are at site, you are engineer assigned to site to carry out series of steam - condensate line flushing. You will have to find the properties (e.g. enthalpy, entropy, density, etc) for superheated steam , steam & condensate at saturated conditions and subcooled condensate, one of the easiest method is use a FREE Excel Add-in (which recommended many months ago in "Steam - Condensate Useful Links...").

One fine day you are at site, you are engineer assigned to site to carry out series of steam - condensate line flushing. You will have to find the properties (e.g. enthalpy, entropy, density, etc) for superheated steam , steam & condensate at saturated conditions and subcooled condensate, one of the easiest method is use a FREE Excel Add-in (which recommended many months ago in "Steam - Condensate Useful Links...").Note : If you are dealing with Steam & Condensate, there are plenty of good stuff in Steam - Condensate Useful Links...(Click HERE)

Water97_v13.xla (Alternative download) is a very useful MS EXCEL Add-In for calculating thermodynamic and transport properties of water and steam using the industrial standard IAPWS-IF97.In the event you would like to back check what you have installed and programmed is correct or quick checking on the properties or you do not want to goes through the difficulties, you may find this Steam-Condensate Calculator (click here) pretty useful for you. Thanks to Jacques for recent recommendation.

If you found any good & reliable related sites, please drop me a note (click HERE) for sharing...

Related Topic

- Steam - Condensate Useful Links...

- FREE & Reliable Control Valve Sizing Software

- aspenONE V2006.5 ... RELEASED

- FREE & reliable Pressure Relief Valve Sizing Software

- Paul Muller - Process Solution Provider...@Heat Exchanger

- Optimized Gas Treating, Inc. (OGT) - Experts in CO2-Amine

- ChemSep™ LITE - FREE Distillation, Absorption & Extraction Simulation

Tuesday, February 12, 2008

Display problem ? Click HERE

There are many extremely useful control valve handbooks and articles available online and FREE for read and download as discussed in "Useful Documents Related to Control Valve". This post would recommend a few FREE and reliable CONTROL VALVE SIZING software available ONLINE.

Most of you might aware present of them, but the intention of this post is really to list out the good control valve sizing software for easy access and future reference. In the event you have forgotten where you park them, you may always come back to download.

Most of you might aware present of them, but the intention of this post is really to list out the good control valve sizing software for easy access and future reference. In the event you have forgotten where you park them, you may always come back to download.Simple request to you... if you found lost link and new version of them, please drop a note by click HERE.

Recommended UTILITY :

Clipmarks - Useful Utility for Blogger and Publisher

FIRSTVUE Sizing Software (Version 1.0.ab)

FIRSTVUE Sizing Software (Version 1.0.ab)Emerson FISHER

The FIRSTVUE Valve Sizing Program helps you identify the control valve package best suited to each set of service conditions. You can use FIRSTVUE's powerful valve selection features to specify either a single control valve or hundreds with minimal effort. As a bonus, FIRSTVUE offers Export/Import capabilities that let you take advantage of plant engineering, design and maintenance programs such as Intergraph Corporation's INtools and Instrument Data Manager (IDM). FIRSTVUE also allows the Export and Import of data from most other data management systems via Comma Delimited Text Files and a simple mapping function.

ValSpeQ

ValSpeQDresser-Masoneilan

ValSpeQ, a full function, Windows based multi-configurator for Valve & Level sizing, selection and specification tool. This version of ValSpeQ is intended for Masoneilan sales and sales support personnel as well as sales representatives and agents. ValSpeQ is designed to be an effective tool for quickly sizing a few valves to generating complete proposal documentation for large quotes. Now ValSpeQ supports configuring of Levels too. As a valve configurator ValSpeQ offers flexibility yet is consistent in its validation of valve, actuator and accessory selections. Indeed, the tool is structured so that user cannot select invalid combinations of components. Tool output reliability is also assured through sizing calculations and noise prediction methods that are entirely consistent with the latest ISA/IEC standards. Moreover, regular maintenance of the ValSpeQ product database and standardized formatting of output documents leads to tool accuracy and consistency. As a common platform for sales support worldwide, the ValSpeQ product database and output documents are intended to be Masoneilan corporate standards.

ValveWorks

ValveWorksWarren Control

ValveWorks® is a state of the art FREE program, offering sizing solutions for Globe or Rotary 2-Way or 3- Way valves based on ISA 75.01 and proven International standards. Engineering technology is the foundation for Instrumentation and Controls advances. ValveWorks® is such a product from Warren Controls Inc. - a milestone in the proper application of Control Valves. Now with basic application information, you can see exactly which control valve will provide the accurate control needed, and clearly identifies how well specific choices will perform in the application with no guess work.

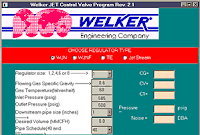

Control Valve Sizing Program

Control Valve Sizing ProgramWelker Engineering

The valve sizing program was designed to help you select the best Welker Jet® Control Valve for your particular needs. Simply fill in the blanks with your specs and the application will automatically calculate the proper sized valve for your application. It's quick. It's easy. And it's the best way to select the Welker Jet® Control Valve that's right for you.

Check out installation TIPS

Related Topic

- WELKER Jet Contorl Valve Handbook

- Useful Documents Related to Control Valve - Updated

- Useful Documents Related to Control Valve

- Hydraulic Design Of Liquid with Pump Circuit - A revision kit...

- Hydraulic Design of Liquid Piping Systems - A revision kit...

- Why bypass Non-Return Valve (NRV) ?

Labels: Control valve, Software

Wednesday, January 16, 2008

Display problem ? Click HERE

ASPENTECH has just released it aspenONE V2006.5 on Jan 16th 2008. aspenONE user is encourage to upgrade (upon request) their present version to enjoy the following features.

ASPENTECH has just released it aspenONE V2006.5 on Jan 16th 2008. aspenONE user is encourage to upgrade (upon request) their present version to enjoy the following features.- Superior aspenONE integration enables better cross-application workflows

- Vista compatibility exploits the latest Microsoft OS release

- Improved quality and reliability optimize performance

- New features and enhancements simplify usability

- Improved online help saves valuable time

- Updated documentation and training ensure faster deployment

USEFUL INFORMATION :

USEFUL INFORMATION :- Read more about aspenONE (Click HERE).

- What's new about aspenONE V2006.5 ? (For user only - Click HERE)

- AspenTech Software Upgrades and Licenses

One of the objective of upgrading a software is to use a bug-FREE / bug-rectified software. Many experiences shown that upgraded version creates NEW bug due to bugs removal activities. This has really made feel uneasy whenever a project demand for upgraded version.

What is your experience ?

Related Post

What is your experience ?

Related Post

- Bug in ASPENTECH HYSYS 2006 Dynamic Depressuring Fisher Valve model

- Controlled and Non-controlled Type Depressuring

- How to apply valve equation in HYSYS Depressuring ?

- Simulate Trayed & Packed bed column in HYSYS

- Correct model and thermo package in Amine system simulation using HYSYS

- How to differentiate MASS lower heating value and Volumetric Lower heating value (gas) in HYSYS ?

- Paul Muller - Process Solution Provider...@Heat Exchanger

- Optimized Gas Treating, Inc. (OGT) - Experts in CO2-Amine

- ChemSep™ LITE - FREE Distillation, Absorption & Extraction Simulation

Sunday, January 13, 2008

Recommended :

- Tips on Succession in FREE Subscription

- Subscribe FREE - Chemical Processing

Pressure relief load determination is a common task carry out by process engineer whilst Pressure Relief Valve (PRV) sizing and selection is normally conducted by vendor with the coordination with Instrumentation Engineer (most companies). However, pre-selection and sizing of PRV may need to be carried by process engineer during conceptual and Front End Engineering Design (FEED) stage in order to provide best estimate of information for Flare system design. Thus, PRV sizing is considered one of the important task for process engineer.

Pressure relief load determination is a common task carry out by process engineer whilst Pressure Relief Valve (PRV) sizing and selection is normally conducted by vendor with the coordination with Instrumentation Engineer (most companies). However, pre-selection and sizing of PRV may need to be carried by process engineer during conceptual and Front End Engineering Design (FEED) stage in order to provide best estimate of information for Flare system design. Thus, PRV sizing is considered one of the important task for process engineer.

There are many Pressure relief valve vendors offer free PRV sizing program. However, a few out there are really good, reliable and impressive. Farris SIZEMASTER, Dresser CONSOLIDATED SRVS and Tyco PRV2SIZE consider one of those.

- Tips on Succession in FREE Subscription

- Subscribe FREE - Chemical Processing

Pressure relief load determination is a common task carry out by process engineer whilst Pressure Relief Valve (PRV) sizing and selection is normally conducted by vendor with the coordination with Instrumentation Engineer (most companies). However, pre-selection and sizing of PRV may need to be carried by process engineer during conceptual and Front End Engineering Design (FEED) stage in order to provide best estimate of information for Flare system design. Thus, PRV sizing is considered one of the important task for process engineer.

Pressure relief load determination is a common task carry out by process engineer whilst Pressure Relief Valve (PRV) sizing and selection is normally conducted by vendor with the coordination with Instrumentation Engineer (most companies). However, pre-selection and sizing of PRV may need to be carried by process engineer during conceptual and Front End Engineering Design (FEED) stage in order to provide best estimate of information for Flare system design. Thus, PRV sizing is considered one of the important task for process engineer.There are many Pressure relief valve vendors offer free PRV sizing program. However, a few out there are really good, reliable and impressive. Farris SIZEMASTER, Dresser CONSOLIDATED SRVS and Tyco PRV2SIZE consider one of those.

Farris SIZEMASTER

Farris SIZEMASTERFarris

Now you can accurately size and select a pressure relief valves for any combination of process applications with SizeMaster™ Mark IV pressure relief valve engineering software. This program for Windows® (all versions) brings unprecedented integration of standard engineering practice to the task of sizing and selecting pressure relief valves.

With SizeMaster Mark IV software, you can define as few as one or as many as 64 different sizing scenarios including blocked flow, fire, thermal and tube rupture, from a scenario matrix grid. Selection of the pressure relief valve is automatically based on the relief area of the worst case scenario. Various Wizards make the most complicated task simple; for instance, the Capacity Wizard allows you to determine accurate vapor generation for vessels of all types.

Download Farris SIZEMASTER

Dresser CONSOLIDATED SRVS

DresserConsolidated's SRVS™ Pressure Relief Valve (PRV) sizing and selection software and SRVS-INtools, automated PRV sizing and selection software for INtools.

Download Dresser CONSOLIDATED SRVS

Tyco PRV2SIZE

TycoTYCO PRV2SIZE Pressure Relief Valve and Vent Sizing & Selection software is the latest innovation in pressure relief sizing software to meet demands for a simple and integrated solution. It is the first program from Tyco Flow Control to offer integrated sizing, selection, and configuration of Anderson Greenwood, Crosby, and Varec brand pressure relief devices.

Download Tyco PRV2SIZE

If you are aware of other PSV sizing software which is considered reliable, why not let us know ? OR if you are friend of one of above softwares, why not share your thought with us ?

Related Post

- Useful Documents Related to Pressure Relief Valve (PRV) - Part 3

- Useful Documents Related to Pressure Relief Valve (PRV) - Part 2

- Useful Documents Related to Pressure Relief Valve (PRV) - Part 1

- Should maximum recommended wall temperature (Tw) for carbon steel vessel used as design temperature ?

- Should we consider JET FIRE for Pressure Relief Valve (PSV) load determination ?

Labels: Overpressure Protection, Pressure Relief Device, Software

Saturday, June 9, 2007

Paul Mueller Company, a company incepted in 1940, specializes in the design and manufacture of stainless steel processing systems and equipment for the food, dairy, beverage, pharmaceutical, chemical, biotech, and bottled water industries.

Paul Mueller Company, a company incepted in 1940, specializes in the design and manufacture of stainless steel processing systems and equipment for the food, dairy, beverage, pharmaceutical, chemical, biotech, and bottled water industries.Products ranges

Processing Systems and Equipment

In this post, i would like to bring to you it HEAT TRANSFER equipment. MUELLER manufactures :

FREE Sizing program & Articles available in MUELLER :

Accu-Therm Sizing Program

Product Brochures available FREE for download

Ad 375-2

Your Heat Transfer Solutions Provider

Ad 386

Accu-Therm® Plate Heat Exchangers

AT-1601-11

Accu-Therm Plate Heat Exchangers

AT-1607-9

Free-Flow Plate Heat Exchangers

AT-1609-2

Accu-Therm Advantage in Metal Finishing

AT-1610-1

Accu-Therm Back Flush System

AT-1629-3

Accu-Therm Double-Wall Heat Exchangers

AT-1635

Accu-Therm Typical HVAC Cooling Applications

AT-1638-2

Accu-Therm Sanitary Plate Heat Exchangers

AT-1648

New Larger Accu-Therm Plates

BP-1800-1

Brazed Plate Heat Exchangers

O-1453

ASME Plate Heat Exchanger Spec Sheet

O-1454

Non-ASME Plate Heat Exchanger Spec Sheet

TP-103-7

Temp-Plate® Immersion Sections for Metal Finishing Industry

TP-107-2

Temp-Plate Idea Book

TP-108-13

All About Temp-Plate®

TP-111-3

Temp-Plate Energy Banks

TP-406-3

Heat Transfer Solutions

TP-408-3

Double-Embossed Temp-Plate Clamp-On Sections

TP-412-3

Clamp-On Heat Transfer Surface

TP-413-2

Clamp-On Temp-Plate Heat Transfer Surface

TP-433-1

Panel-Coil™

Your Heat Transfer Solutions Provider

Ad 386

Accu-Therm® Plate Heat Exchangers

AT-1601-11

Accu-Therm Plate Heat Exchangers

AT-1607-9

Free-Flow Plate Heat Exchangers

AT-1609-2

Accu-Therm Advantage in Metal Finishing

AT-1610-1

Accu-Therm Back Flush System

AT-1629-3

Accu-Therm Double-Wall Heat Exchangers

AT-1635

Accu-Therm Typical HVAC Cooling Applications

AT-1638-2

Accu-Therm Sanitary Plate Heat Exchangers

AT-1648

New Larger Accu-Therm Plates

BP-1800-1

Brazed Plate Heat Exchangers

O-1453

ASME Plate Heat Exchanger Spec Sheet

O-1454

Non-ASME Plate Heat Exchanger Spec Sheet

TP-103-7

Temp-Plate® Immersion Sections for Metal Finishing Industry

TP-107-2

Temp-Plate Idea Book

TP-108-13

All About Temp-Plate®

TP-111-3

Temp-Plate Energy Banks

TP-406-3

Heat Transfer Solutions

TP-408-3

Double-Embossed Temp-Plate Clamp-On Sections

TP-412-3

Clamp-On Heat Transfer Surface

TP-413-2

Clamp-On Temp-Plate Heat Transfer Surface

TP-433-1

Panel-Coil™

Continue receive FREE stuff & Update.......Subscribe by Email

Labels: Heat Exchanger, PHE, Software

Friday, May 25, 2007

Carbon Dioxide (CO2) is known as one of industrial waste gas causing global warming...there are number of measures are implemented to reduce global warming. CO2 reduction measures are CO2 capturing, reinjection into aquifer, injection into reservior for well maintenance, gas injection for enhanced oil recovery (EOR), etc.

Above efforts will reduce CO2 release into atmosphere. However, recycling CO2 will increase quantity of CO2 in oil and result serious corrosion problem. Hence it needs to be removed from the flashed gas (from unstabilised oil). CO2 removal technology using amine absorption has been used for many years. Recently i found a website (OGT) where the founders, Ralph Weiland and Jack Dingman are those experts in this technology.

Optimized Gas Treating, Inc. (OGT) was established in 1992 by Ralph Weiland and Jack Dingman for the single purpose of providing a commercial version of a Windows-based software package for simulating acid gas removal with aqueous alkanolamines that uses a fundamental mass and heat transfer rate approach to column modeling. ProTreat™ is the culmination of more than 30 years of research in gas treating supported by government and industry in both academic and commercial environments. ProTreat is our sole product. Consequently, it receives our undivided attention in maintaining and enhancing its capabilities so that it remains the premier software package for gas treating with amines. OGT’s principals are recognized world experts in most aspects of gas treating — they offer a total of nearly 60 years of relevant experience.

Some FREE articles offered by OGT :

Column related

WebWorm

Labels: Absorption, Amine, Column, Distillation, Equilibrium, Extraction, Global warming, Modelling, Packed Column, Packing, Process simulation, Software, Technology, Tower internals

Tuesday, May 1, 2007

ChemSep is a software system for simulation of distillation, absorption, and extraction operations.

Built in features

- integrates flash calculations

- classic equilibrium stage column model

- non-equilibrium or rate-based column model

- export results to spreadsheet, text, and html.

- stand-alone mode as well as in flowsheet via CAPE-OPEN

Special features ChemSep 6 for Windows

- Residue Curve Maps

- Ternary VLE diagrams

- Parametric Study Mode

- CAPE OPEN (CO) compliance

- SulCol integration

- Constant relative volatility thermodynamic model

- New features added in 2006

FREE download

ChemSep-LITE is available for FREE download and is now CAPE-OPEN compliant (article in NPT). It can be used as a stand-alone column simulator or as a unit operation model inside any CO compliant flowsheet simulation program such as ASPEN Plus or COCO. ChemSep-LITE includes the equilibrium column model and is limited to 5 components and 50 stages.

ChemSep book is available FREE for download

"Performance of a commercial scale 14% hole area sieve tray", Ind. Eng. Chem. Proc. Des. Dev., Vol. 21 (1982) pp. 712-717. FRI total reflux experiments published by T. Yanagi, M. Sakata

[Excel]

Note :Installed ChemSep LITE in order to be able to recalculate the spreadsheet.

PhD. thesis of Harry Kooijman, Dynamic Nonequilibrium Column Simulation,

PhD. thesis of Arnoud Higler, A Nonequilibrium Model for Reactive Distillation.

PhD. thesis of Richard Baur, Modeling Reactive Distillation Dynamics.

WebWorm

Labels: Absorption, Distillation, Equilibrium, Extraction, Non-Equilibrium, Software