Saturday, December 6, 2008

Display problem ? Click HERE

Recommended :

- Subscribe FREE - Processing Magazine

- Tips on Succession in FREE Subscription

Pressure safety valve (PSV) or pressure relief valve (PRV) (let’s call it PSV in general) is commonly used to protect a pressure containment part i.e. vessel, column, etc from overpressure. It is one of the code approved type of overpressure protection devices. This type of device is reclosing type where the mechanism of devices is designed such that it will stop relief when the pressure is reduced to it reseat pressure. Besides PSV, rupture disc (RD) and rupture pin are also code approved type of overpressure devices. This type of device is non-reclosing type where it will continue to relief until all inventory is completely evacuated from the system or with operator intervention.

Pressure safety valve (PSV) or pressure relief valve (PRV) (let’s call it PSV in general) is commonly used to protect a pressure containment part i.e. vessel, column, etc from overpressure. It is one of the code approved type of overpressure protection devices. This type of device is reclosing type where the mechanism of devices is designed such that it will stop relief when the pressure is reduced to it reseat pressure. Besides PSV, rupture disc (RD) and rupture pin are also code approved type of overpressure devices. This type of device is non-reclosing type where it will continue to relief until all inventory is completely evacuated from the system or with operator intervention.

- Subscribe FREE - Processing Magazine

- Tips on Succession in FREE Subscription

Pressure safety valve (PSV) or pressure relief valve (PRV) (let’s call it PSV in general) is commonly used to protect a pressure containment part i.e. vessel, column, etc from overpressure. It is one of the code approved type of overpressure protection devices. This type of device is reclosing type where the mechanism of devices is designed such that it will stop relief when the pressure is reduced to it reseat pressure. Besides PSV, rupture disc (RD) and rupture pin are also code approved type of overpressure devices. This type of device is non-reclosing type where it will continue to relief until all inventory is completely evacuated from the system or with operator intervention.

Pressure safety valve (PSV) or pressure relief valve (PRV) (let’s call it PSV in general) is commonly used to protect a pressure containment part i.e. vessel, column, etc from overpressure. It is one of the code approved type of overpressure protection devices. This type of device is reclosing type where the mechanism of devices is designed such that it will stop relief when the pressure is reduced to it reseat pressure. Besides PSV, rupture disc (RD) and rupture pin are also code approved type of overpressure devices. This type of device is non-reclosing type where it will continue to relief until all inventory is completely evacuated from the system or with operator intervention.There are three main common types of PSV :

- Conventional spring loaded direct acting PSV

- Balanced-bellow and/or balanced-piston PSV

- Pilot operated PSV

Conventional spring loaded direct acting PSV

A conventional spring loaded direct acting PSV is a spring loaded pressure relief valve whose operational characteristics are directly affected by changes in the back pressure. There are several topics related to back pressure :

A conventional spring loaded direct acting PSV is a spring loaded pressure relief valve whose operational characteristics are directly affected by changes in the back pressure. There are several topics related to back pressure :

- Back Pressure Affect Conventional PSV Set Pressure : Case Study #2 - Non-Bonnect Vent

- Back Pressure Affect Conventional PSV Set Pressure : Case Study #1 - Bonnect Vent to ATM

- How Back Pressure Affect Conventional PSV Set Pressure Subject to It Vent

- Several Impacts of Backpressure on Conventional PRV

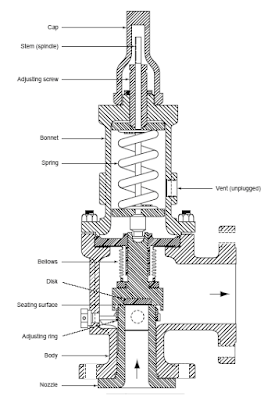

Conventional spring loaded direct acting PSV (typical)

Balanced-bellow and/or balanced piston PSV

A balanced-bellow and/or balanced piston PSV is a spring loaded pressure relief valve that incorporates a bellows or other means for minimizing the effect of back pressure on the operational characteristics of the valve. See below images.

Compare to conventional spring loaded direct acting PSV, a bellow is added around the disc holder and spindle. The intention of this bellow is basically eliminate the area difference between the disc holder (surface exposing to PSV outlet) and nozzle area (surface exposing to PSV outlet) so that to eliminate the impact of back pressure on the performance of PSV. A balanced-bellow PSV typically can tolerate back pressure upto 30% (some may goes upto 50%) of the set pressure of PSV. This shall be confirmed by PSV manufacturer.

Balanced-bellow PSV (typical)

Balanced-piston PSV (typical)

Subscribes to FREE Hydrocarbon Processing

Pilot operated PSV

Pilot operated PSV

Compare to a balanced-bellow PSV, a balanced-piston PSV bonnet is extended with insertion block and balanced piston. This type of PSV is commonly used in system with fluid temperature potentially drop below sub-zero i.e. NGL recovery plant, LNG production plant, etc during relief and in case of leakage or passing.

Compare to a balanced-bellow PSV, a balanced-piston PSV bonnet is extended with insertion block and balanced piston. This type of PSV is commonly used in system with fluid temperature potentially drop below sub-zero i.e. NGL recovery plant, LNG production plant, etc during relief and in case of leakage or passing.

A pilot operated PSV is a pressure relief valve in which the major relieving device or main valve is combined with and controlled by a self actuated auxiliary pressure relief valve (pilot). See below images. T

Pop action & flowing type pilot operated PSV

Compare to conventional type and balanced type PSV, pilot operate PSV design and construction have following advantages :

Following is a video clip presented typical construction and operation of a conventional PSV.

Related Posts

- allow PSV inlet non-recoverable line loss higher than 3% of PSV set pressure (conventional PSV and balanced bellow PSV limit to maximum of 3% of set pressure). Read more "concerns & recommendations on PSV INLET line" and "How to Resolve Issue with PSV Inlet Line Loss Exceeded 3% of Set pressure"

- allow maximum operating pressure upto 95% of PSV set pressure. Some PSV can allow upto 97-98% of PSV set pressure (as compare to 90% set pressure which typically for conventional and balanced bellow PSV)

- can tolerate very high back pressure (>50% of set pressure. Required manufacturer confirmation)

Following is a video clip presented typical construction and operation of a conventional PSV.

Typical construction and operation of a conventional PSV

(Click here to view from Browser - Recommended)

(Click here to view from Browser - Recommended)

Related Posts

Labels: Overpressure Protection, Pressure Relief Device

2 Comments:

Great details on the common types of the pressure safety valves (PSVs) - I especially enjoy the illustrations. Thanks for posting.

-Jack

Thanks for sharing information about visualise pressure safety valve (PSV) assemblies & operation. I just bookmarked and will share social websites.

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home