Saturday, July 18, 2009

Display problem ? Click HERE

Recommended :

- Tips on Succession in FREE Subscription

- Subscribes to FREE Hydrocarbon Processing

High frequency acoustic Excitation downstream of pressure reducing device and potential of downstream piping failure on Acoustic Induced Vibration (AIV) has raised concern in many process plant

High frequency acoustic Excitation downstream of pressure reducing device and potential of downstream piping failure on Acoustic Induced Vibration (AIV) has raised concern in many process plant

Earlier post "Extra Attention to Common Point and Similarity on AIV Failure" has discussed the common points and similarity of AIV such as typical failure location, system experienced failure in the past, failure time & period and Mach no. An engineer assessing AIV shall pay extra attention in these factors.

There are several methods have been discussed earlier in assessing AIV problem. There are "D-method" and "D/t-method". These two methods are widely used by many engineering contractor and consultants in many previous projects. There is another method, the Energy Input method or "E-method" which has been introduced in mid 1990.

Energy Input or E-method In Assessing AIV

The "E-method" is focus on the acoustic energy transmitted along the pipe, downstream of pressure reducing devices. The acoustic energy can be measured by Ma2.dP where Ma2 is the Mach number at downstream pipe and dP is the pressure drop across pressure reducing devices. The higher the acoustic energy or Ma2.dP, higher the risk for AIV failure.

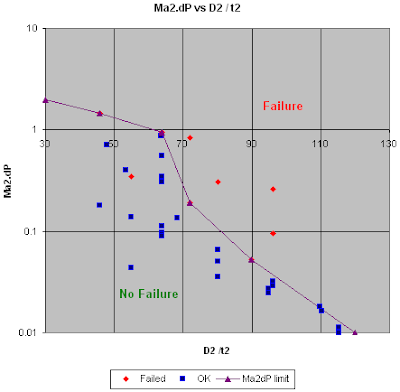

Similar to the other two methods, based on data available in Carucci & Mueller (1982) studies, "No failure" and "Failure" points have been plotted in following chart with Ma2.dP versus Pipe Diameter / Wall thickness (D/t).

Note :

1) A "failure" point (54.8, 0.35) is below curve. It is failed on bad welding. No further failure after good welding.

2) Red point are "failure" point and Blue point are "No failure" point

From above chart a clear distinctive limit line can be established. This line may be used to assess potential failure of piping downstream of pressure reducing device. Any point above the line potentially fail on AIV, piping treatment or redesign required to minimise the risk of AIV failure.

*As limit line is straight or following any pattern, a representative equation is yet to be developed.

Related Topic

- Tips on Succession in FREE Subscription

- Subscribes to FREE Hydrocarbon Processing

Earlier post "Extra Attention to Common Point and Similarity on AIV Failure" has discussed the common points and similarity of AIV such as typical failure location, system experienced failure in the past, failure time & period and Mach no. An engineer assessing AIV shall pay extra attention in these factors.

There are several methods have been discussed earlier in assessing AIV problem. There are "D-method" and "D/t-method". These two methods are widely used by many engineering contractor and consultants in many previous projects. There is another method, the Energy Input method or "E-method" which has been introduced in mid 1990.

Energy Input or E-method In Assessing AIV

The "E-method" is focus on the acoustic energy transmitted along the pipe, downstream of pressure reducing devices. The acoustic energy can be measured by Ma2.dP where Ma2 is the Mach number at downstream pipe and dP is the pressure drop across pressure reducing devices. The higher the acoustic energy or Ma2.dP, higher the risk for AIV failure.

Similar to the other two methods, based on data available in Carucci & Mueller (1982) studies, "No failure" and "Failure" points have been plotted in following chart with Ma2.dP versus Pipe Diameter / Wall thickness (D/t).

Note :

1) A "failure" point (54.8, 0.35) is below curve. It is failed on bad welding. No further failure after good welding.

2) Red point are "failure" point and Blue point are "No failure" point

From above chart a clear distinctive limit line can be established. This line may be used to assess potential failure of piping downstream of pressure reducing device. Any point above the line potentially fail on AIV, piping treatment or redesign required to minimise the risk of AIV failure.

*As limit line is straight or following any pattern, a representative equation is yet to be developed.

Related Topic

- Assess AIV with "D/t-method" with Polynomial PWL Limit Line

- Assess AIV with "D/t-method" with Logarithm PWL Limit Line

- Extra Attention to Common Point and Similarity on AIV Failure

- Piping Excitation When Expose to Acoustic Energy

- Acoustic Induced Vibration (AIV) Fatigue

- Sound Power Level (PWL) Prediction from AIV Aspect

- Several Criteria and Constraints for Flare Network - Piping

0 Comments:

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home