Thursday, September 6, 2007

In one the recent depleted field debottlenecking project, new Booster Compression unit will be installed to boost the depleted well fluid pressure to meet high delivery pressure while maintaining the production forecast market demand.

As this unit will be installed on existing platform, space and weight constraint are the MAJOR issues. Many efforts have been implemented in order to reduce new installation space and weight. One of them is to reduce the Lube Oil Cooler Size.

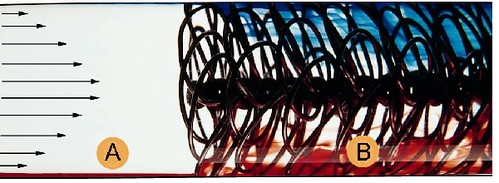

The following image demonstrates a wire matrix turbulator by hiTRAN

Wire matrix turbulator, known as a HiTRAN® Matrix Element, is inserted into inner tube of Heat Exchanger. The basic principle is to promote fluid mixing, convert laminar flow to turbulence flow pattern, maintaining turbulence flow pattern and improve tube-side heat and mass transfer.

From above image,

- region (A) is laminar flow conditions

- region (B) is turbulence caused by the use of hiTRAN matrix tube Inserts

See below the comparison between Compressor lube oil cooler (Air-Cooled Heat Exchanger) with and without turbulator :

Number of tube rows above each other 5* (with turbulator) 10* (without turbulator)

Width 4* m(with turbulator) 7.3* m (without turbulator)

Length 7.9* m (with tubulator) 12.2* m (without turbulator)

Height 7.2* m (with turbulator) 9.3* m (without turbulator)

* For reference only

Turbulator has significantly reduce the space consume and weight and it ensure the project to proceed to installation phase. Idea of using turbulator is one of the success story in debottlenecking project especially those have space and weight constraints.

Further Reading

As this unit will be installed on existing platform, space and weight constraint are the MAJOR issues. Many efforts have been implemented in order to reduce new installation space and weight. One of them is to reduce the Lube Oil Cooler Size.

How to reduce lube oil cooler size while meeting duty and flow ?

Turbulator

Turbulator

The following image demonstrates a wire matrix turbulator by hiTRAN

Wire matrix turbulator, known as a HiTRAN® Matrix Element, is inserted into inner tube of Heat Exchanger. The basic principle is to promote fluid mixing, convert laminar flow to turbulence flow pattern, maintaining turbulence flow pattern and improve tube-side heat and mass transfer.

From above image,

- region (A) is laminar flow conditions

- region (B) is turbulence caused by the use of hiTRAN matrix tube Inserts

See below the comparison between Compressor lube oil cooler (Air-Cooled Heat Exchanger) with and without turbulator :

Number of tube rows above each other 5* (with turbulator) 10* (without turbulator)

Width 4* m(with turbulator) 7.3* m (without turbulator)

Length 7.9* m (with tubulator) 12.2* m (without turbulator)

Height 7.2* m (with turbulator) 9.3* m (without turbulator)

* For reference only

Turbulator has significantly reduce the space consume and weight and it ensure the project to proceed to installation phase. Idea of using turbulator is one of the success story in debottlenecking project especially those have space and weight constraints.

Further Reading

Labels: Air Cooler, Heat Exchanger

0 Comments:

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home