Sunday, August 26, 2007

This question has been raised by many engineers and debated in many discussion.

Careful review on the relief valve structure, process fluid passing through a nozzle instead of an orifice. Those many researchers such as Dr. Ron Darby for multiphase flow in Direct Integration method (HDI), Dr Fauske & Dr Henry for two phase relief in Homogeneous Non-equilibrium model (HNE), Dr. Joseph Leung for two phase flow in Omega method, etc have modelled a relief valve as a nozzle.

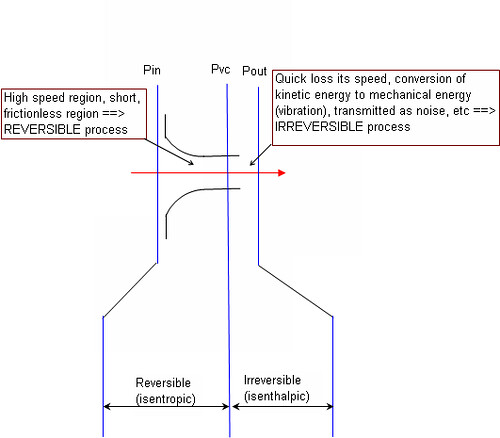

Classical and conventional studies informed us that vena contracta (VC) will only occur in sharp edge orifice. However, the flow restricting area in a relief valve as decribed by many well knowed specialists is not an orifice, but is actually a nozzle. Thus there is NO vena contracta downstream of the nozzle.

Phenomenon of flow through a nozzle in relief valve is extremely fast. Choked flow is possible occur in some location "A" in the nozzle instead of outside the nozzle (may be closed to the exit end), from the inlet to "A" will be a REVERSIBLE process which generally accepted by most of the specialists. Thus, it is ISENTROPIC process. From location "A" to PSV outlet, the system is expanded and change in state. It will be slow down. There will be transformation energy loss however the enthalpy is maintain constant (ISENTHALPIC). This process is IRREVERSIBLE. "A" is viewed as vena contracta in the relief valve's nozzle. Those in sizing a relief valve, we ignore the frictional loss in the nozzle and consider ISENTROPIC process. However, from expansion process via safety valve (Vena contracta to relief outlet), the process will be ISENTHALPIC.

Related topics

If you benefits from this post, buy me some sweets

Labels: Modelling, Pressure Relief Device, PSV, Thermodynamic

0 Comments:

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home