Tuesday, August 21, 2007

What are the differences between Duplex Stainless Steel, Medium Alloy Duplex, 22% Cr, SAF 2205 and UNS 31803 ?

What are the differences between Duplex Stainless Steel, Medium Alloy Duplex, 22% Cr, SAF 2205 and UNS 31803 ?They are refer to same metal. Duplex Stainless Steel and Medium Alloy Duplex is general (layman) term and commonly used across discipline. Material specialist like to call it 22% Cr. SAF 2205 is the trade name where procurement people like put it in purchase order. Different terms used sometime may results confusion and miscommunication. Thus, Unified Numbering System (UNS) has been created for standardization and easy administration. This system is widely use in North American included Canada.

“The Unified Numbering System for Metals and Alloys (UNS) provides a means of correlating many internationally used metal and alloy numbering systems administered by societies, trade associations, and those individual users and producers of metals and alloys. It provides the uniformity necessary for efficient indexing, record keeping, data storage and retrieval, and cross-referencing.”

Above was extracted from book <<Metals & Alloys in the Unified Numbering Systems >>. This book (in CD) provides information on :

- UNS number

- Description

- Common trade names and alloy designations

- Cross-reference organization

- Cross-reference specifications

- Chemical composition

The UNS is managed jointly by the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE).

The UNS number (for "Unified Numbering System for Metals and Alloys") is a systematic approach where each metal is designated by a LETTER followed by five NUMBERS. The number is unique and composition-based of commercial materials. It is used for material reference but it does not guarantee any performance specifications and/or exact composition.

Following are overview of common commercial metals / alloys using UNS system :

- Axxxxx - Aluminium Alloys

- Cxxxxx - Copper Alloys, including Brass and Bronze

- Fxxxxx - Iron, including Ductile Irons and Cast Irons

- Gxxxxx - Carbon and Alloy Steels

- Hxxxxx - Steels - AISI H Steels

- Jxxxxx - Steels - Cast

- Kxxxxx - Steels, including Maraging, Stainless, HSLA, Iron-Base Superalloys

- L5xxxx - Lead Alloys, including Babbit Alloys and Solders

- M1xxxx - Magnesium Alloys

- Nxxxxx - Nickel Alloys

- Rxxxxx - Refractory Alloys

- R03xxx- Molybdenum Alloys

- R04xxx- Niobium (Columbium) Alloys

- R05xxx- Tantalum Alloys

- R3xxxx- Cobalt Alloys

- R5xxxx- Titanium Alloys

- R6xxxx- Zirconium Alloys

- Sxxxxx - Stainless Steels, including Precipitation Hardening and Iron-Based Superalloys

- Txxxxx - Tool Steels

- Zxxxxx - Zinc Alloys

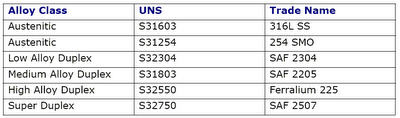

Typical example :

Relating Topics

- Chloride stress corrosion cracking and use of correct MOC for seawater

- How Chloride stress corrosion cracking Lookslike ?

Labels: Corrosion Resistance Material, Material, UNS

2 Comments:

JW, this is very interesting and informative post...Keep it up man....

Zaki,

Thanks. Will do...

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home