Friday, September 28, 2007

Heat exchanger sleeving, a money-saving technology generally associated with the electric power industry, is drawing increasing interest from engineers in the chemical process industries (CPI), as well.

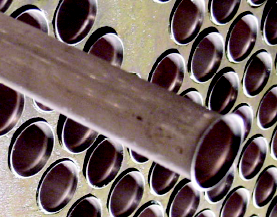

Heat exchanger sleeving, a money-saving technology generally associated with the electric power industry, is drawing increasing interest from engineers in the chemical process industries (CPI), as well.Sleeving consists of expanding thin tubes (sleeves) into the tubes of a heat exchanger. The expanding process produces a residual, interfacial fit pressure between the outside surface of the sleeve and the inside surface of the tube. The sleeves may be short, for instance about 6 to 16 in., or may extend for the full straight length of the tubes. Typical sleeve thicknesses are 0.01 to 0.03 in., depending upon material of construction and thickness of the original tubes. In addition to the expansion step, sometimes the inner end of the sleeves is welded to the inside wall of the tube.

In tubular heat transfer equipment in power plants, sleeving has long been used for one or more of these purposes:

- To reduce the prospect of inlet-end tube erosion (short sleeves for this purpose are also called ferrules, and their use is called ferruling)

- To restore tubes to service that had been plugged by plant personnel because of known perforations in discrete, identifiable locations

- To restore tubes to service that had been plugged because their walls had become excessively thin

- To bridge failures in discrete locations of tubes that are otherwise intact; for example, if a tube has a circular crack just beyond the inner face of the tubesheet

Related Topics

Labels: Heat Exchanger, Life, Sleeving

0 Comments:

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home