Thursday, August 21, 2008

Display problem ? Click HERE

Recommended :

- Subscribe FREE - World Pumpv (USA & Europe only)

- Tips on Succession in FREE Subscription

The discussion on pump cavitation have been circulated around what is pump cavitation ? how destructive a cavitation ? how cavitation sound & looks like ? what the relationship between NPSHa & NPSHr ? how to increases NPSHa to minimize / avoid cavitation ?... We understood that a minimum flow shall be maintained to minimize cavitation, avoid impeller damage and extend pump lifespan. "Rule-of-thumb For Minimum Flow Recycle" discussed few factors possibly determining the minimum flow recirculated around centrifugal pump.

- Subscribe FREE - World Pumpv (USA & Europe only)

- Tips on Succession in FREE Subscription

The discussion on pump cavitation have been circulated around what is pump cavitation ? how destructive a cavitation ? how cavitation sound & looks like ? what the relationship between NPSHa & NPSHr ? how to increases NPSHa to minimize / avoid cavitation ?... We understood that a minimum flow shall be maintained to minimize cavitation, avoid impeller damage and extend pump lifespan. "Rule-of-thumb For Minimum Flow Recycle" discussed few factors possibly determining the minimum flow recirculated around centrifugal pump.

What are the Centrifugal Pump Minimum Flow Control Strategies can be considered ?

There are number ways to implement minimum flow protection strategy for centrifugal pump. Typically they are:

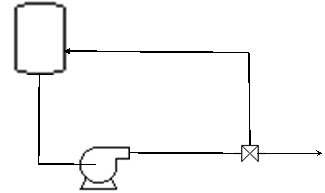

(i) A restriction orifice on pump discharge recycle line

(ii) A flow meter on pump discharge with control valve on recycle line

(iii) Use Automatic Recirculation Valves (ARC) valve

(iv) Flow-Delta P and flow meter on pump discharge with control valve on recycle line

Fig. 1 restriction orifice on pump discharge recycle line

Fig. 2 Flow meter on pump discharge with control valve on recycle line

Fig. 3 Automatic Recirculation Valves (ARC) valve

Fig. 4 Flow-Delta P and flow meter on pump discharge with control valve on recycle

Comparison

The following list out the advantages and disadvantages for above four options

Restriction orifices

- Simple installation

- Maintenance free

- Large pump

- Waste energy all time

- Limit maximum pump output.

Orifice plate in the discharge line

- No continuous recycle thus energy saving

- consumes energy and also slightly reduces pump capacity.

- Using orifice plate to measure flow will results high inaccuracy e.g. minimum flow is 40% of maximum flow, 7% of the set point may be expected.

ARC valve

- Simple & effective

- Lack of flexibility.

- Unstable operation

- expensive

Sketches below show outlook and operation of an ARC valve

- Similar to orifice plate option

- Good option for load sharing of pumps in parallel installation

Restriction orifice option is the most common option adopted in many applications with LOW capacity system and a process engineer is advisable to consider this option. However, for HIGH system and appreciable energy losses is possible, a process engineer is advised to consider flow orifice with control valve option. ARC valve may be a good option to consider if process engineer is well aware of the fluid characteristics and familiar with the operation & dynamic of ARC valve. For very high capacity system and load sharing may be expected, process engineer may consider Flow-Delta P option.

Related Topic

- Quick Check Pump Performance Using Motor Data and Field Measure Current

- Is PumpSmart Right Solution for You ?

- Special Flowmeter & Piping Release...

- Vortex Breaker to Avoid Vapor Entrainment

- Estimate Minimum Submergence to Avoid Vapor Entrainment

- Estimate Pump Power Consumption without Vendor Information

- Trim Centrifugal Pump Impeller for Reduced Head

- Quick Check if Pump Performance Curve (Water) is Good for High Viscosity Fluid

Labels: Minimum flow, Pump

1 Comments:

I design a small process plant with pumps utilization range from small 2 BHP pumps up to 1700 BHP pumps, 25 psi head to 1500 psig head and flow from 10 gpm to 2000 gpm.

My Engineering sense told me that not all of these pumps need to have a minimum flow controller. It may not applied on small pumps.

What is your opinion about that and if you agree what is the typical minimum pump size that require minimum flow control (protection)

rayz

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home