Sunday, November 16, 2008

Display problem ? Click HERE

Recommended :

Subscribe FREE - Processing Magazine

Check valves or Non-return valves (NRV) are normally installed in piping to avoid back flow. Rotating equipment such as pump, compressor, etc will always be equipped with NRV(s) on the discharge to avoid back flow when rotating equipment is shut. Back flow creates severe surging to the rotating equipment and potentially damage the equipment. In certain process system, NRV will be employed to avoid contamination, overheating, etc due to back flow.

Check valves or Non-return valves (NRV) are normally installed in piping to avoid back flow. Rotating equipment such as pump, compressor, etc will always be equipped with NRV(s) on the discharge to avoid back flow when rotating equipment is shut. Back flow creates severe surging to the rotating equipment and potentially damage the equipment. In certain process system, NRV will be employed to avoid contamination, overheating, etc due to back flow.Check valves or Non-return valves (NRV) is basically an automatic valve open to allow forward flow and close to against reverse flow. In principle, it split into four basic types. There are swing, dual-plate, tilting disc and lifting type. Wrong selection of check valve type can leads to operability problem, leakage and continual maintenance issue.

Lift Check valves

- higher pressure drop is expected.

- equipped with small return spring to facilitate valve closure on reverse flow

- two type of seat. hard seat for for high differential pressure sealing and resilient seat for low differential pressure sealing

- shortest travel length. Fastest response.

- excellent performance for low and/or pulsating flows

- not good for fluid with particles

- Body install horizontal with disc / piston vertically

- Small check valve range from 1/2" to 2" lift piston type check valve

- Prefer operate in full open position

Minimum Recommended Line Velocity, Vmin (ft/s) = 12 SQRT (v)

where

v = Specific Volume of the Fluid (ft3/lb)

Lift Check Valve

Swing Check Valve

- Tight sealing / shut-off

- Low pressure drop

- Susceptible to water hammer

- Not good for low flow and/or pulsating flow

- Vertical (upward flow) & horizontal installation

- Easiest check valve to maintain

- Prefer operate in full open position

Swing check valves should be sized such that the flow velocity in the line is sufficient to hold the disc in the fully open position.

Minimum Recommended Line Velocity, Vmin (ft/s) = 75 SQRT(v)

where

v = Specific Volume of the Fluid (ft3/lb)

Swing Check Valve

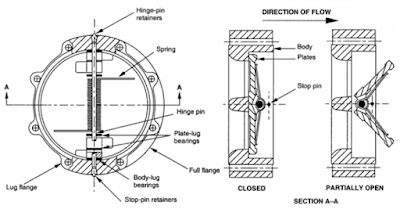

Dual plate Check valve

The characteristic of dual plate check valve is pretty same as swing check valve.

- low pressure drop

- Not good for low flow and/or pulsating flow

- Vertical (upward flow) & horizontal installation

- Faster opening and closure compare to swing check valve

- Susceptible to water hammer (lesser than Swing check valve)

- Prefer operate in full open position

Dual Plate Check Valve

Tilting Disc Check Valves

- Fast opening and closing without damage to disc and seat

- Stable at low and pulsating flows

- Moderate pressure drop. Lower than lifting check valve but higher than swing check valve

- Vertical (upward) & horizontal installation

- Moderate tight sealing

- Prefer operate in full open position

Minimum Recommended Line Velocity, Vmin (ft/s) = 24 sqrt (v)

where

v = Specific Volume of the Fluid (ft3/lb)

Tilting Disc Check Valve

Selection Consideration

There are four (4) main criteria shall be considered for the selection of check valve type :

Related Post

There are four (4) main criteria shall be considered for the selection of check valve type :

- non-slam characteristic

- pressure loss

- cost

- application

Comparative rating for each type of check valve have been provided for these criteria (specifically first two technical criteria). These rating will be plotted on a Check Valve Comparative Selection Chart and together budget for final selection. Read more in "Design and Selection of Check Valve".

Related Post

- Several Strategies To Minimize Relief Capacity in Back-Flow Scenario

- How to predict Check Valve Slam ?

- How to Select a Check Valve (NRV) Quantitatively ?

- Why Redundant NRV in Series within a Line ?

- Why bypass Non-Return Valve (NRV) ?

- Potential Problem associate with Double NRV in Series within a Line

- Basis & Tips on Setting Centrifugal Pump "Warming" Recycle Flow

Labels: Fluid Flow, Hydraulic, NRV, Surge

1 Comments:

Short, precise, efficient.

I like it!

Post a Comment

Let us know your opinion !!! You can use some HTML tags, such as <b>, <i>, <a>

Subscribe to Post Comments [Atom]

Home:

<< Home